3D laser scan

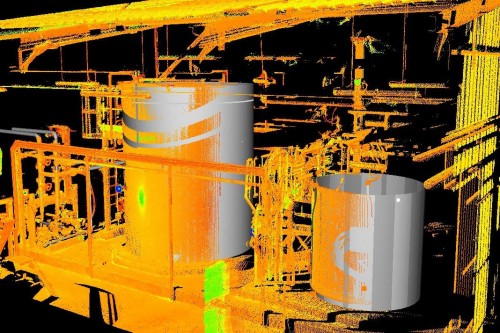

One of the main problems in certain projects is the lack of reliable and updated documentation of the current state of their facilities. In order to solve this problem quickly and efficiently, at Protón Ingenieros we are committed to the latest technologies, incorporating 3D scanning using a laser scanner for all our services.

We have our own Leica 3D laser stations (C10 and BLK360 G2) with which we can achieve millimetre precision in new designs, extensions, revampings and modifications of existing installations, ensuring the effectiveness of our design and avoiding assembly errors that generate unforeseen and in general very high costs.

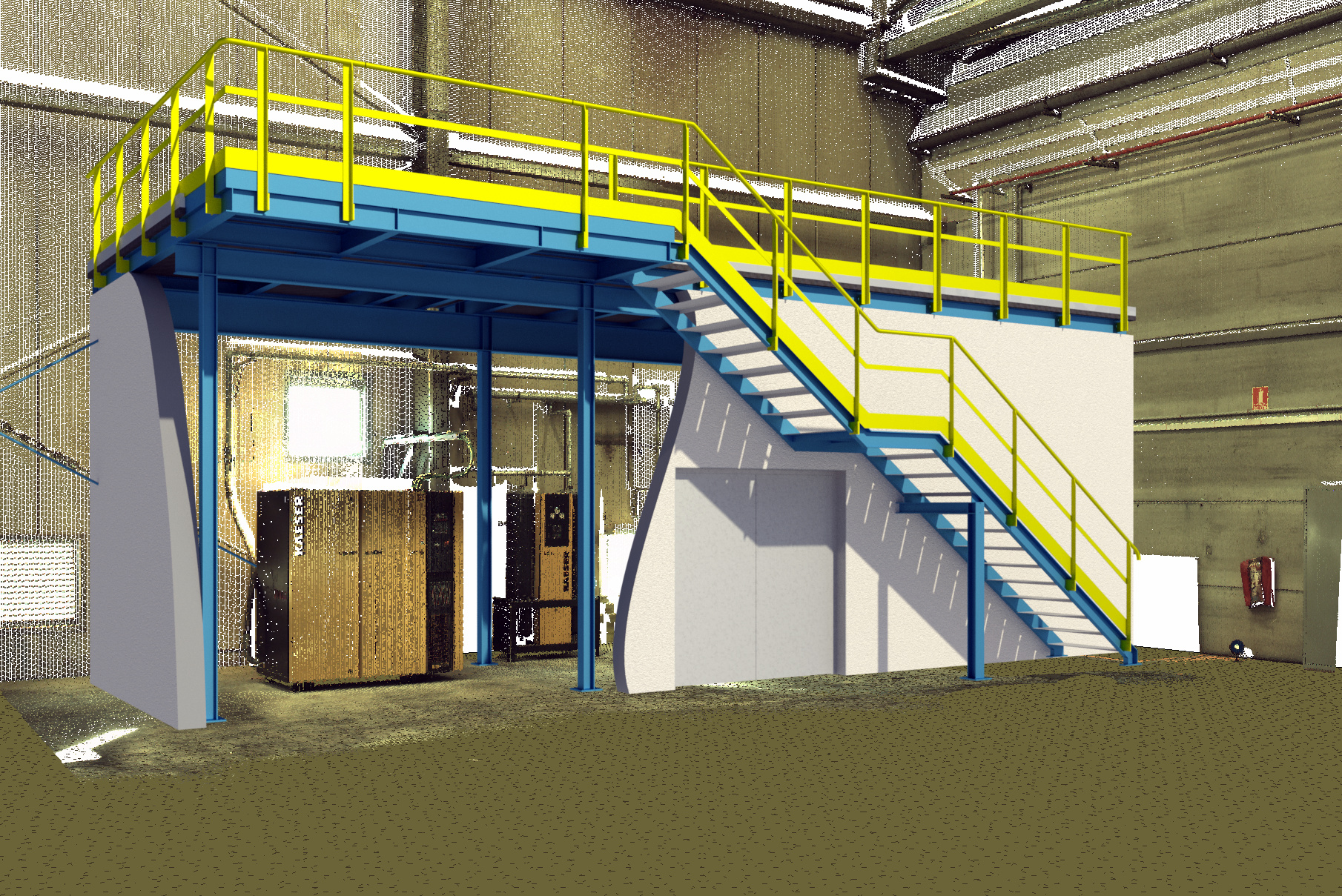

We also use specific point cloud modelling software to complete the integral solution with the rest of our 3D BIM design tools.

Among the tasks that we can carry out with this team, we highlight:

- Generation of “As built” documentation: We accurately and reliably capture the geometry of existing “As found” and / or “As built” facilities

- Interference study: After scanning complex areas, we studied the interference of new pipeline layouts, additional structures, equipment, wiring, etc., without the need for subsequent field checks.

- We also carry out modularization and assembly simulations.

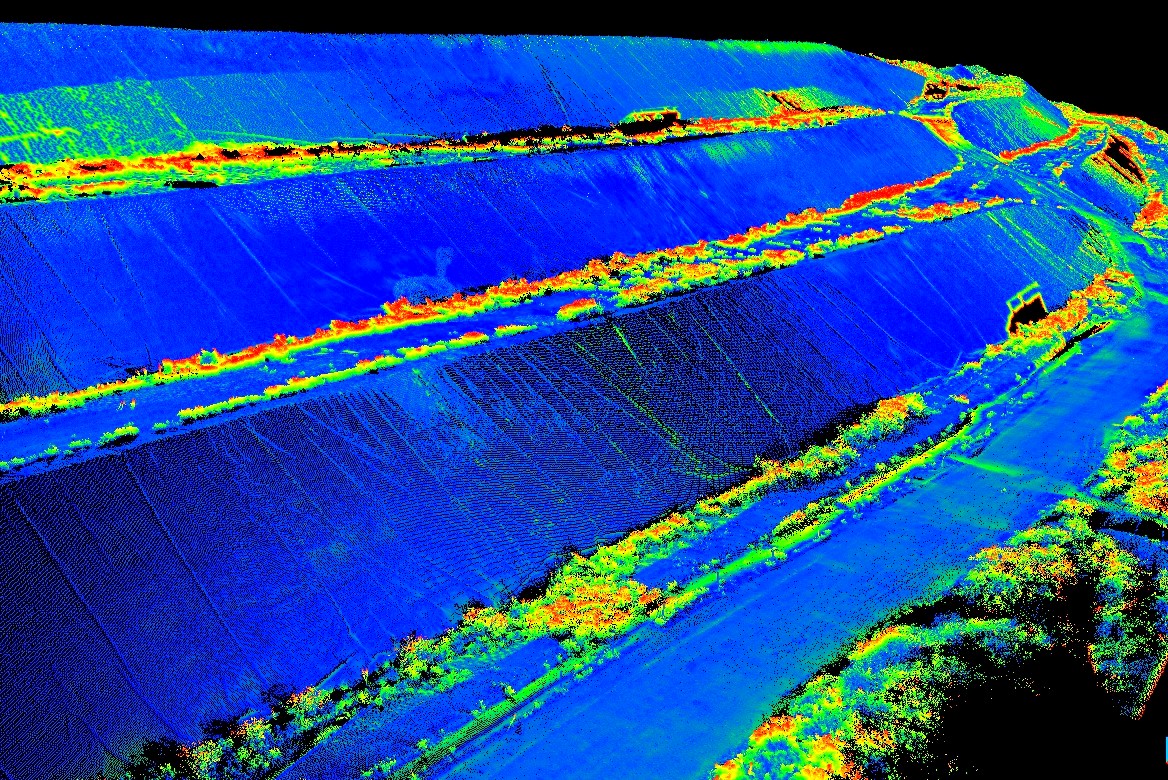

- Dimensional control: We use 3D scanning to detect deviations in manufacturing and assembly tolerances during execution. It is possible to know the deviation of surfaces with respect to regular geometries: surfaces of revolution, flatness, collapse and alignments of the structure, pipe axes, deformations, etc.

- Study of structural pathologies.

- Study of deformations and displacements (3D mesh) both applied to equipment or terrain. Specific application for movement control of landfill slopes, mining open pit, etc.

- Safety and evacuation studies.

- 3D analysis of construction progress.

3D laser scan

One of the main problems in certain projects is the lack of reliable and updated documentation of the current state of their facilities. In order to solve this problem quickly and efficiently, at Protón Ingenieros we are committed to the latest technologies, incorporating 3D scanning using a laser scanner for all our services.

We have our own 3D laser station (Leica ScanStation) with which we can achieve millimeter precision in new designs, extensions, revampings and modifications of existing installations, ensuring the effectiveness of our design and avoiding assembly errors that generate unforeseen and in general very high costs.

We also use point cloud modeling software (Cyclone Model and Cloudworxs, from Leica), through which we complete the integral solution with the rest of our 3D BIM design tools.

Among the tasks that we can carry out with this team, we highlight:

- Generation of “As built” documentation: We accurately and reliably capture the geometry of existing “As found” and / or “As built” facilities

- Interference study: After scanning complex areas, we studied the interference of new pipeline layouts, additional structures, equipment, wiring, etc., without the need for subsequent field checks.

- We also carry out modularization and assembly simulations.

- Dimensional control: We use 3D scanning to detect deviations in manufacturing and assembly tolerances during execution. It is possible to know the deviation of surfaces with respect to regular geometries: surfaces of revolution, flatness, collapse and alignments of the structure, pipe axes, deformations, etc.

- Study of structural pathologies.

- Study of deformations and displacements (3D mesh) both applied to equipment or terrain. Specific application for movement control of landfill slopes, mining open pit, etc.

- Safety and evacuation studies.

- 3D analysis of construction progress.